FERMA-MOBILE

FERMA-MOBILE Microclimate controllers

Microclimate controllers

Poultry weighing scales

Poultry weighing scales Silo scales

Silo scales Feed and water dispensing

Feed and water dispensing Lighting

Lighting Alarms

Alarms Extension modules

Extension modules Sensors

Sensors Accessories

Accessories Software

Software Warranty terms

Warranty terms Download

DownloadThe VIRGO-INL controller

The VIRGO-INL controller

The VIRGO-INL controller is an electronic device used to control microclimate in livestock buildings with gravity ventilation, heating and spraying (cooling and humidification) on the basis of measurement of temperature, humidity and carbon dioxide concentration. The microclimate control is performed by the control of servomotors that open or close air inlets (e.g. chimney flaps, side curtains). The controller enables to control several servomotors of chimney flaps and curtains by connection of INLET-010 modules (max. 4 for chimneys and max. 4 for curtains). During its operation the VIRGO-INL controller records the history: values of measured parameters, alarms, control. That enables the continuous control of the breeding process as well as data archiving. After reading the history to PC computer it is possible to present it in the shape of tables and charts. An in-built communication interface provides the possibility of connection of many VIRGO-INL controllers in the network and to control their operation by means of PC computer- it is also possible to configure the system to remote control- via the Internet.

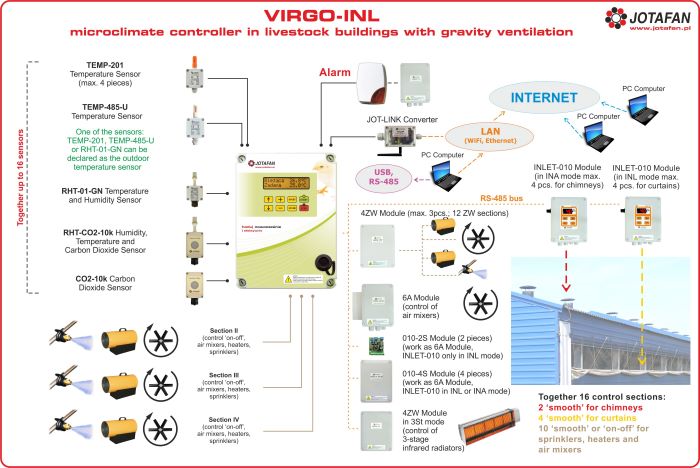

Wiring diagram of the VIRGO-INL controller with sensors and modules control:

In the VIRGO-INL controller can be used up to:

- 16 sensors (temperature, humidity, carbon dioxide concentration),

- 16 control sections (4 in-built, 12 external; ventilation, heating, spraying, air mixers).

There are available the following functions:

- ventilation on the basis of temperature, humidity and CO2 concentration,

- target temperature set manually or automatic change according to curve,

- night temperature (change of temperature when lighting is off in order to improve the welfare and efficiency of the breeding process),

- periodical ventilation (also with the function of minimum ventilation),

- the control of humidity level: dehumidification and humidification,

- heating,

- cooling by spraying,

- operation of air mixers on the basis of temperature difference between sensors and together with heaters,

- cooperation with 3 stage heaters,

- alarms,

- recording of the operation history with date and time (alarms and cyclical saving of parameters, daily indicators),

- connection to PC computer and remote control of many VIRGO controllers – also via the Internet (dedicated software is the FARM software).

| Supply voltage | 230 V, 50 Hz |

| Class of anti-electric shock protection | I |

| Types of control outputs of ON/OFF section | Electronic switch ~230 V, 50 Hz |

| Type of control of above mentioned section | Two-position (ON/OFF type) |

| Load current of electronic switches of section | Imax: 0,5A (230 V, 50 Hz), Imin: 150 mA (ab. 35 W) |

| Fuses in the power circuit of section | Ceramic 0,5 A, 250 V (IL≥1500 A) |

| Relay alarm output | Umax: 24 V DC, Imax: 200 mA, R: 8,2 Ω |

| Type of serial communication input | RS-485 |

| Range of setting of target temperature | –5 ÷ +50 °C, resolution 0,1 °C |

| Range of temperature measurement | –25 ÷ +69,9 °C, resolution 0,1 °C |

| Range of temperature operation of TEMP-201 sensor | –25 ÷ +70 °C |

| Resolution of a relative humidity setting | 1 % |

| Resolution of a CO2 concentration setting | 50 ppm |

| Temperature in immediate vicinity of the controller | 0 ÷ 40 °C |

| Ambient relative humidity | 10 ÷ 90 % (non-condensing) |

| Ingress protection class | IP55 |

| Housing dimensions (height x width x thickness) | 315 x 235 x 130 mm |

| Device weight (without a temperature sensor) | 2,1 kg |

| Type of a cooperative temperature sensor | TEMP-201, TEMP-485-U, RHT-01-GN, CO2-10K, RHT-CO2-10K |

Automatic controllers

Automatic controllers Print

Print